News

LATEST NEWS AND EVENTS FROM THE SCHOOL OF ENGINEERING

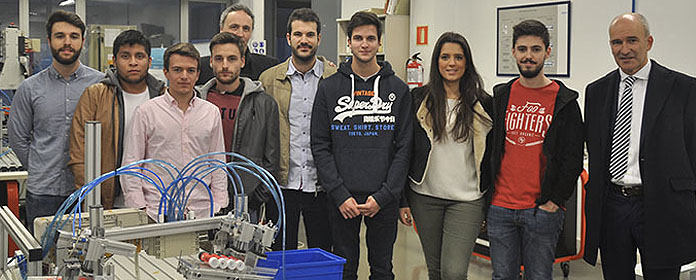

ABC Compressors awards an award of 600 euros to students of Tecnun for the quality of a pneumatics project

The goal of this collaboration is to encourage the company's participation in the evaluation of a practice related to its professional activity.

The director general manager of ABC Compressors, Carlos Martín, has awarded an award of 600 euros to several students from Mechanical Engineering of Tecnun for the "robustness, reliability and originality" of their project, a machine dedicated to the placement of plugs on glue sticks. The prototype, designed and assembled by 4th year students as part of the subject Pneumatics and Oleohydraulics course, received the best grade from the jury. The general director of ABC Compressors, Carlos Martín; the technical director , Demetrio San Adrián; and the advisor, Lucio Arizaga, have highlighted the high level of industrialization of the machine developed by the young people, which makes it worthy of the first award.

This collaboration has taken place on the occasion of the agreement that the School signed with ABC Compressors last September 26, 2017. The goal of this initiative is to encourage the participation of the company, dedicated to manufacturing compressors for the food and petrochemical sectors, in subjects related to their professional activity. "We want to gain notoriety in the School because we need to hire engineers trained by Tecnun", said the general director , Carlos Martin. "In addition to the motivation for students to be evaluated by professionals who are engaged in a related activity," he added.

"This practice is carried out in a professional context so that students learn to meet different milestones to create a machine with pneumatic technology and make it work," explains professor Gorka Sánchez. The students use different programs from design in which they virtually create their project and the teachers correct the different deliveries. "There's the core topic. With two weeks to go until the end of subject they have the actuators and the parts with which to assemble the machines, work that they do in the last sessions."